RXG20

Keywords:

RXG20

- 产品描述

- Order process

- Order notice

- Return notice

- Customer service

-

- Commodity name: RXG20

Widely used in various electrical equipment and electronic instruments for DC or AC for buck shunt load.

Widely used in various electrical equipment and electronic instruments for DC or AC for buck shunt load.

Specifications

The wire-wound fixed resistor is fixed by a clamp ring, longitudinally drawn, and coated with a high-temperature resistant insulating coating on the surface. It is suitable for small current and large resistance; it has the characteristics of large power, strong overload resistance, reliable performance and convenient use.

-

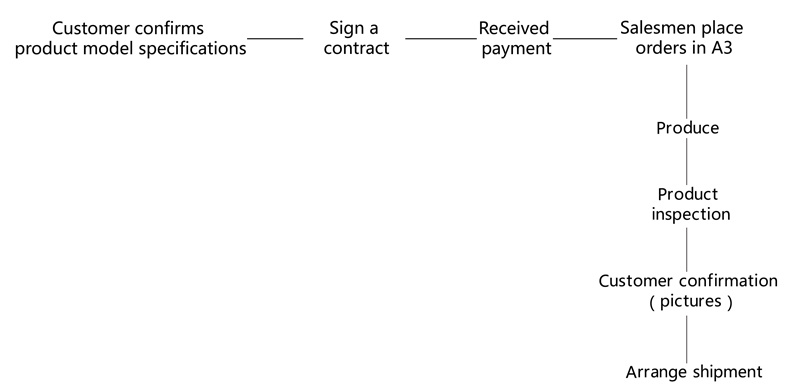

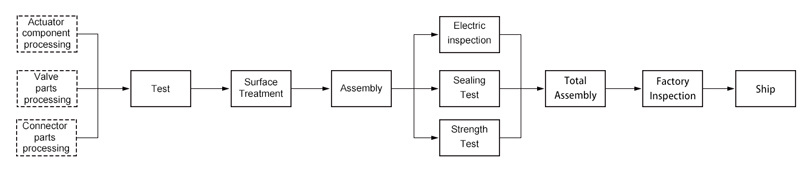

Order production process

Production Process

-

In general ,wire resistor element have some quantities stock,small order lead time :3-4 working days ;big order,please contact with sales.

-

Reasons for Return

Product time limit

Solutions

Remarks

quality problem

Date to 12 months

Exchange or free repair; reimbursement for freight

Written reasons

More than 12 months

Cost charges for repairing or collecting spare parts

Special Treatment for Special Causes

Misdistribution of business

Return within 2 months (against bill of lading)

Documents to Compensate for Return Fees

Products should be intact

User mistakenly purchased goods

Return within 2 months (against bill of lading)

10% discount

Customized products

Within 3 months from the date of leaving the factory

30% discount

The specific discount depends on the situation.

More than 3 months

No refund or exchange

Backlog of unsatisfactory sales

Within 24 months from the date of discharge

20% discount

After-sales Service Department

Opinions shall prevail.24 to 36 months

50% discount

Over 36 months

No refund or exchange

Out of Sale Products

Withdrawal of notice

No refund or exchange

-

Customer Service Center is one of the most important departments of Heli Automation Instrument Co., Ltd. Her main job is to accept customer comprehensive business consulting, provide technical support to customers; accept, coordinate, handle customer complaints, solve customer's difficult problems; actively communicate with customers, contact, understand customer's feelings and needs, and timely customer information Feedback to all relevant management departments and proper handling.

The Customer Service Center has a Customer Management Department and a Technical Service Department. The customer management department mainly accepts the customer's comprehensive business consulting, and the technical service department mainly provides customers with technical support and solutions for pre-sale, sale and after-sales products. In order to ensure that every customer can get satisfactory service in Heli Automation Instrument Co., Ltd. and maintain good cooperation with the company, we emphasize the pertinence and effectiveness of customer service, and implement the acceptance responsibility system, that is, the customer Every call and every question is responsible for making each other's feelings and understanding. If you have any questions or needs about our products, or have any comments or suggestions about our services, please feel free to contact us and we will do our best to serve you. Your satisfaction is the purpose of our service. The common development of the company and customers is our persistent pursuit.

In the face of the future, all employees of the customer service center will be passionate about warming customers and casting brilliance with service.

Fault check and maintenance

●Mechanical fault check

1. After pulling the switch handle, drive the valve with the handwheel to check whether the hand-electric switch is sensitive and reliable.

2. Check the action and indication of the mechanical opening indicator.

3. If the handwheel does not move and the valve is blocked, the repair valve should be removed. If the valve can be driven by the handwheel, check the electrical part.

4. If the manual operation is normal, there is no interference, and the valve stem does not work, it is necessary to check whether the connection of the valve stem joint is reliable.

●Electrical fault check (check the external controller first, then check the electric device)

1. Check the main power supply and control power supply, relay, fuse and all indicators and switches are normal.

2. Check the motor and replace it if there is a problem.

3. If the micro switch fails, it can be solved by replacing the relevant original.

●Maintenance

It is recommended to perform two routine maintenance or regular maintenance every year.

Gessmann工业操纵杆―德国制造

V28是一款紧凑型操纵杆。常用于电动液压应用。最新的非接触式霍尔技术确保了长寿命和高可靠性。V28系列具有多种输出和手柄选项,可高度定制。

技术细节可能因配置或应用而异!技术数据如有更改,恕不另行通知!

Combinable / compatible products

undefined

Welcome to the consultation.